All you need to know - Challenge Chemical Introduction [Permeation Systems]

Hello and welcome to another post in a series of blogs about our automated permeation systems! In this post we will highlight the key differences...

Hello, and welcome to our first blog in a series on permeation analysis. Permeation systems play an essential role in testing various materials for permeability to chemicals. Today we will look at what makes up a permeation system, focusing on our automated systems that employ a gas chromatograph (GC) for detection. While we, at Ellutia, offer a wide range of systems, this piece will highlight the systems most commonly used for analysing protective glove materials according to EN374 or ASTM F739 standards. We will also explore additional options that can be included to cater to other standards, like warfare agent testing. If you'd like to discuss this further, please feel free to contact us directly.

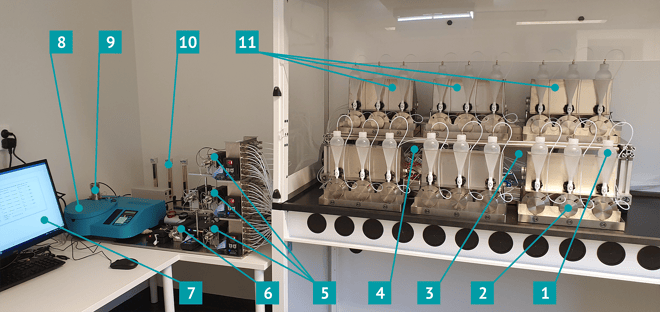

Let's get started by examining the individual components that make up a permeation system:

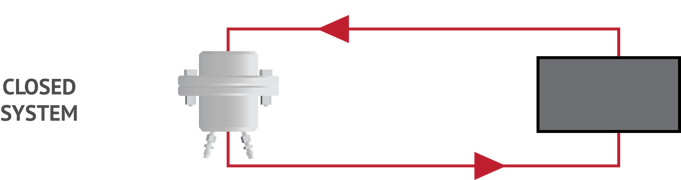

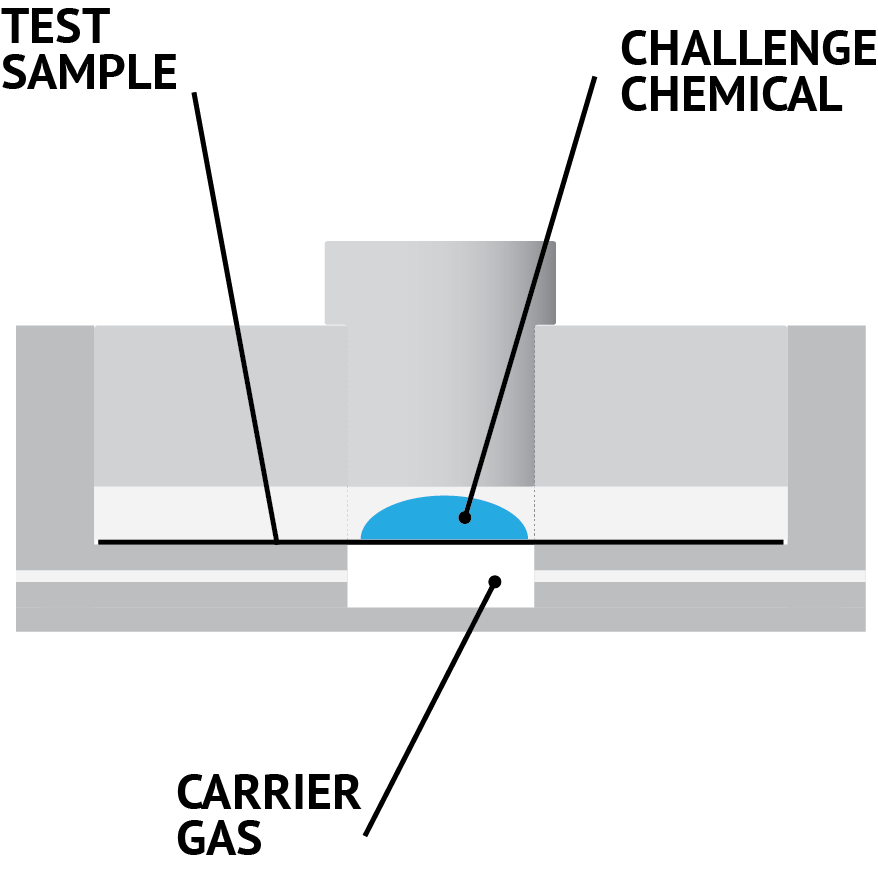

At the forefront of the permeation system is the sampling section, which comprises the analysis cells. These cells bear the responsibility of housing the sample material and challenge chemicals during testing. There are two main configurations of analysis cells for permeation testing.

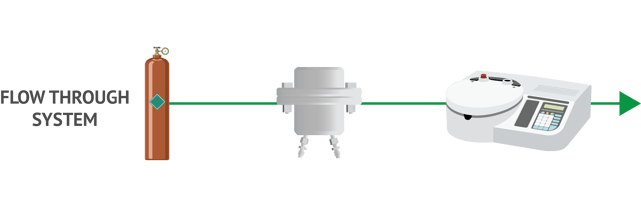

The GC system we are looking at in the post Operates as a flow-through cell rather than a closed-loop one. This means the test material is sandwiched between two halves of the test cell, the top half is where the challenge chemical is introduced and the bottom half is where the carrier gas sweeps any break through chemical to the detector. Cells of different size and volume, and several challenge chemical introduction options are available, depending upon which standards you are working to.

For other standards such as those for warfare systems, we can provide smaller volume cells as per the relevant standards. For analysing air-permeable materials, we can offer cells equipped with a supply of humidified air that sweeps the top compartment. If you have a particular requirement and want to discuss these options further please contact us

A standard system typically includes six cells for triplicate testing, which can be expanded to 18 cells, depending on the testing requirements.

The housing unit is where cells are located during testing. We offer both standard rack versions that just hold the cells in place as well as ones with heating options to control the temperature of the analysis cells during testing, if required.

As standard systems require the operator to manually introduce the challenge chemical into the analysis cell at the correct time. Systems can be upgraded to include automated challenge chemical introduction. This means that instead of manually filling the analysis cell with the challenge chemical, the system will automatically introduce this from a separate reservoir at the correct time. This allows for systems to be operated un-attended and much greater automation of the testing process, especially when dealing with 12 or 18 cells.

To find out more about the difference between manual and automated challenge chemical introduction click here

There are individual flow controllers that control the flow of sweep gas for each cell. A stream selection valve directs the sweep gas from the appropriate cell to the GC for analysis. A port that can be used to manually introduce a sample to enable calibration of the system is included. There is then a sampling valve that collects an exact volume of the sample gas and automatically injects it into the GC. The GC used is an Ellutia 200 Series GC, typically, with a flame ionisation detector, though other detectors can be configured depending upon the samples being analysed. The systems will automatically download the relevant method for the challenge chemical being analysed.

Finally, the signal from the GC passes to the pc where our custom integration and control software can plot the results in real-time.

![]()

Permeation systems can have a lot of variables that depend on your specific goals and requirements. Determining the best configuration for you might seem like a daunting task, but we're here to help. Click the link below to arrange a free initial consultation call. Together, we can review your needs and explore the optimal configuration that would best serve you.

![All you need to know - Challenge Chemical Introduction [Permeation Systems]](https://blog.ellutia.com/hubfs/Thumbnail_V1.png)

Hello and welcome to another post in a series of blogs about our automated permeation systems! In this post we will highlight the key differences...

Most people associate cannabis with THC and CBD. But if you’ve ever wondered why one strain lifts you up while another winds you down, the answer...

We found numerous challenges universities and educational institutions face with their GC systems. After many conversations, we learned that some of...