Nitrites and Nitrates: Understanding the Differences, Risks, and Solutions

Knowing the difference between nitrites and nitrates is key to addressing the challenges they present in pharmaceuticals, environmental monitoring,...

In pharmaceutical manufacturing and quality assurance, nitrites are an emerging area of concern. As scrutiny around nitrosamine contamination intensifies, identifying and controlling nitrite levels is now seen as one of the most effective strategies to reduce risk at source.

This isn’t just about meeting regulatory obligations—it’s about safeguarding patient safety and product integrity.

Nitrites, though not harmful in themselves at trace levels, can readily react with amines to form nitrosamines—a class of compounds known for their carcinogenic and genotoxic potential. Given the ultra-low permissible limits for nitrosamines in medicines (often at the nanogram-per-day level), early-stage screening of nitrite precursors is now critical.

Accurate, rapid, and routine screening for nitrites is an essential pillar in modern nitrosamine risk assessment strategies.

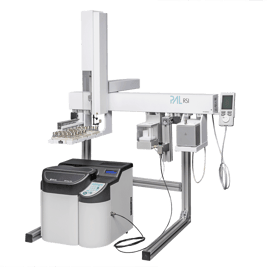

Ellutia’s Automated Total Nitrosamine Analyser (ATNA) is widely recognised for nitrosamine analysis. But the same platform also offers powerful capabilities for nitrite content screening—making it a versatile and forward-thinking solution for pharmaceutical quality control.

This dual functionality enables pharmaceutical manufacturers to:

Screen for nitrites before they become a problem

Monitor nitrosamine formation potential

Reduce time and resources spent on unnecessary deeper testing

The ATNA integrates a suite of purpose-built technologies:

Ellutia 800 Series Thermal Energy Analyser (TEA) for selective detection of nitrogen compounds

Headspace autosampler with vortex mixing and heated agitation for consistent reaction conditions

Custom TEA inlet, enabling unattended operation of up to 120 samples over 12 hours

Sample Preparation: The test sample is treated with hydrobromic acid, triggering a reaction that releases nitric oxide (NO) from any nitrosamines or nitrites present.

Detection Phase: The NO gas diffuses into the headspace and is captured and analysed by the TEA, delivering high-sensitivity results down to low ppb (parts-per-billion) levels.

Early Risk Mitigation

Detect nitrites before they convert into harmful nitrosamines.

Efficient Resource Allocation

Rapidly screen large sample sets and focus confirmatory testing where it matters.

Trace-Level Accuracy

The system's proprietary SPE cartridge ensures clean separation and detection of nitrites and nitrosamines, providing precise insights.

Can ATNA integrate with existing lab workflows?

Yes—it’s designed for modular compatibility and automated throughput.

Is it compliant with regulatory frameworks?

Absolutely. The system supports nitrosamine risk assessments aligned with ICH M7(R1), EMA, and MHRA guidance.

What about return on investment?

By reducing false positives and avoiding unnecessary in-depth analysis, ATNA helps optimise lab productivity and cost-efficiency.

Whether you’re updating your nitrosamine risk assessment or establishing a new screening protocol, the Ellutia team is here to help. We’ll work with you to ensure the ATNA system fits seamlessly into your compliance and quality assurance strategy.

Knowing the difference between nitrites and nitrates is key to addressing the challenges they present in pharmaceuticals, environmental monitoring,...

Nitrosamines continue to draw attention across multiple industries—especially pharmaceuticals, food production, and chemicals—due to their potential...

Nitrosamines are among the most tightly regulated contaminants in pharmaceuticals, food, and tobacco, yet in cannabis, they are barely on the...